NewNews_ChuckRieger_3Dprinting

Posted on November 15, 2020

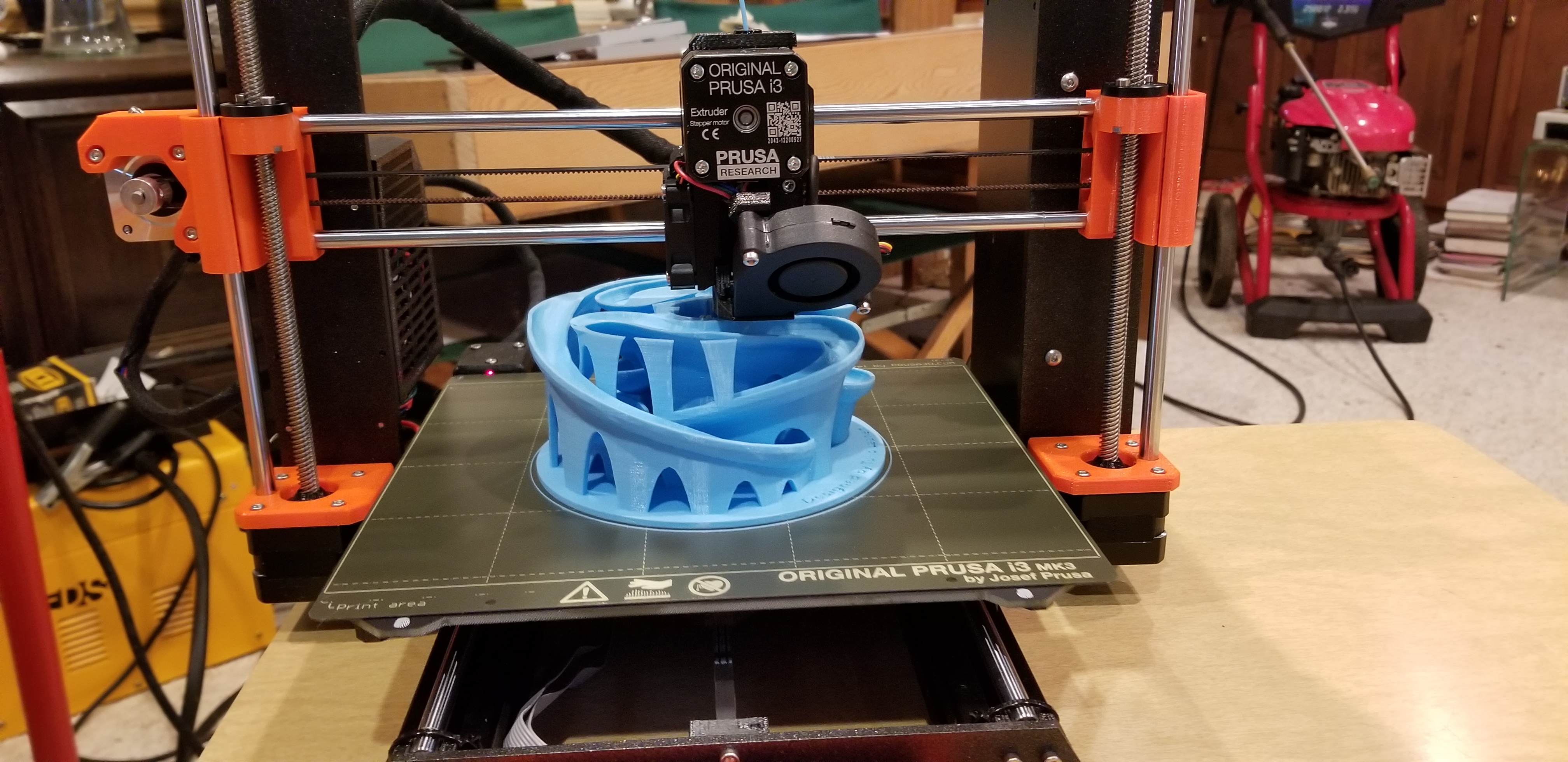

I’ve had a 3D printer for the past five years – a Micro Center Powerspec 3D Pro – but it finally gave up the ghost this summer after thousands of flawless hours of printing. So I gave it a proper burial up in the Gaithersburg recycling center, and ordered a new Prusa i3 MK3S from Prusa Research in Prague. It arrived in August 2020 as a kit, which took about 10 hours to put together. (They have a fully assembled version that costs about $250 more.) I flipped the switch, let it go through its initial calibrations, and everything worked perfectly. So I fired up a test print: a 3D marble machine posted on Thingiverse.com (by Tulio Laanen in the Netherlands), which takes about 23 hours to print. (Click here to see it – I’ve printed 30 or 40 of these over the years for the kids of friends and family – takes about $4 worth of printer filament, which I buy in 1000 foot spools at Micro Center for about $16 each). Here’s what it looked like during that first print:

and here’s a short video of the printer in action: PrintingMarbleMachine. Here’s what the marble machine does after loading up some “marbles” (actually, quarter-inch steel slingshot ammo!): MarbleMachineInAction.

Prusa Research is the brainchild of Josef Prusa, an obviously brilliant 30-year-old design engineer whose company is now acknowledged as a worldwide leading manufacturer of very high quality 3D printers. Remarkably, Prusa 3D prints about 30% of the i3 MK3S kit’s parts in-house, using about 500 copies of the printer itself on the factory floor. Here’s a factory tour video: PrusaFactoryTour. So here we have the dawn of the era of machines producing copies of themselves!!

In addition to downloading and printing many fascinating projects from Thingiverse.com, I also do a lot of original designs for my other projects, mostly using the simple but powerful (and free) Tinkercad.com site. (I also use Autodesk’s Fusion 360, which is a far more powerful design system, but it’s not cheap!) The really powerful idea behind 3D printing is that, once you create a viable design for a particular purpose, you can create as many perfect copies of it as you need, without worrying about whether the parts will consistently fit together! Also, there’s a huge range of printer filament colors and chemical compositions, some of which are quite durable and strong. So I’d have to say that I’m completely hooked on 3D printing!